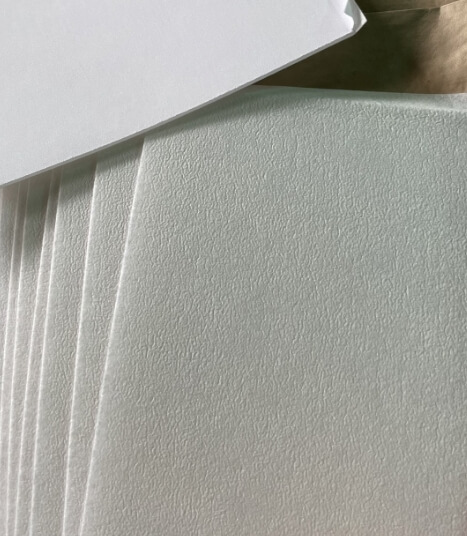

BI-FIT Board

- Unique integrated one-piece patented technology for composite boards.

- Superior Cushioning: It provides better rebound performance compared to traditional materials.

- Waterproofing: The special process embeds fabric within plastic sheets, ensuring waterproofing.

- Support and Stiffness: It offers excellent support and rigidity.

- Durability: With its flexible one-piece molding, it boasts impressive durability.

- Easy Processing: Cold pressing and die cutting make it easy to work with.

- Adhesion: It adheres easily to accessories thanks to its gripping and bonding capabilities.

- Bending Resistance: It can withstand up to 90° of bending.

- Temperature Range: It remains functional within -10°C to 70°C (note that different materials may have varied temperature ranges).

- Hardness Range: Hardness levels range from Shore D 45 to 75 degrees, with the ability to produce single hardness, double hardness, and different material combinations.

- Size: It can be produced with a maximum width of 45cm and a maximum length of 110cm.

- Thickness: Single sheet thickness can reach up to 8mm.

Innovative BI-FIT Technology

BI-FIT board is an innovative and proprietary technology that produces composite plastic boards, polypropylene (PP), and polyethylene (PE) boards. It holds patents in Taiwan, China, the United States, and other countries. Ying Pao Chia became a midsole manufacturer by revolutionizing traditional midsole shoe materials and technology. By integrating plastic materials with fabrics, BI-FIT replaces conventional paperboard midsoles, delivering enhanced support, cushioning, waterproofing, lightweight properties, and durability.

What sets BI-FIT apart is its capacity to directly integrate fabric and plastic during production, allowing easy adhesion to other materials without toxic adhesives. This significantly reduces adverse impacts on both personnel and the environment. BI-FIT incorporates various hardness levels in a single-piece technology. This unique feature enables the front end to withstand 90° of bending resistance, while the back end maintains its rigidity, all the while improving comfort and fit.

Environmental Sustainability and Versatility

Versatility and ease of processing make BI-FIT suitable for a wide range of products and market segments, thereby enhancing its competitiveness and meeting market demands. Ying Pao Chia adheres to global recycling standards (GRS 4.0) by using more than 80% recycled PP or PE plastic to produce BI-FIT patented technology. This environmentally friendly approach contributes to the sustainability of plastic board materials.

- Composite Plastic Boards: These boards can seamlessly integrate plastic with fabrics or other materials, catering to various customer needs for different product applications and market segments.

- Polypropylene (PP) Boards: Our PP boards are non-toxic, lightweight, and heat-resistant, with variable hardness options to match their intended purpose.

- Polyethylene (PE) Boards: Known for their exceptional cold resistance, chemical resilience, and electrical insulation, they can be manufactured in two different hardness levels on a single board.